Kangaroo Point Residence, Thornton Street, Brisbane

Structural Steel Takes Center Stage in Kangaroo Point's New Luxury Residence Thornton

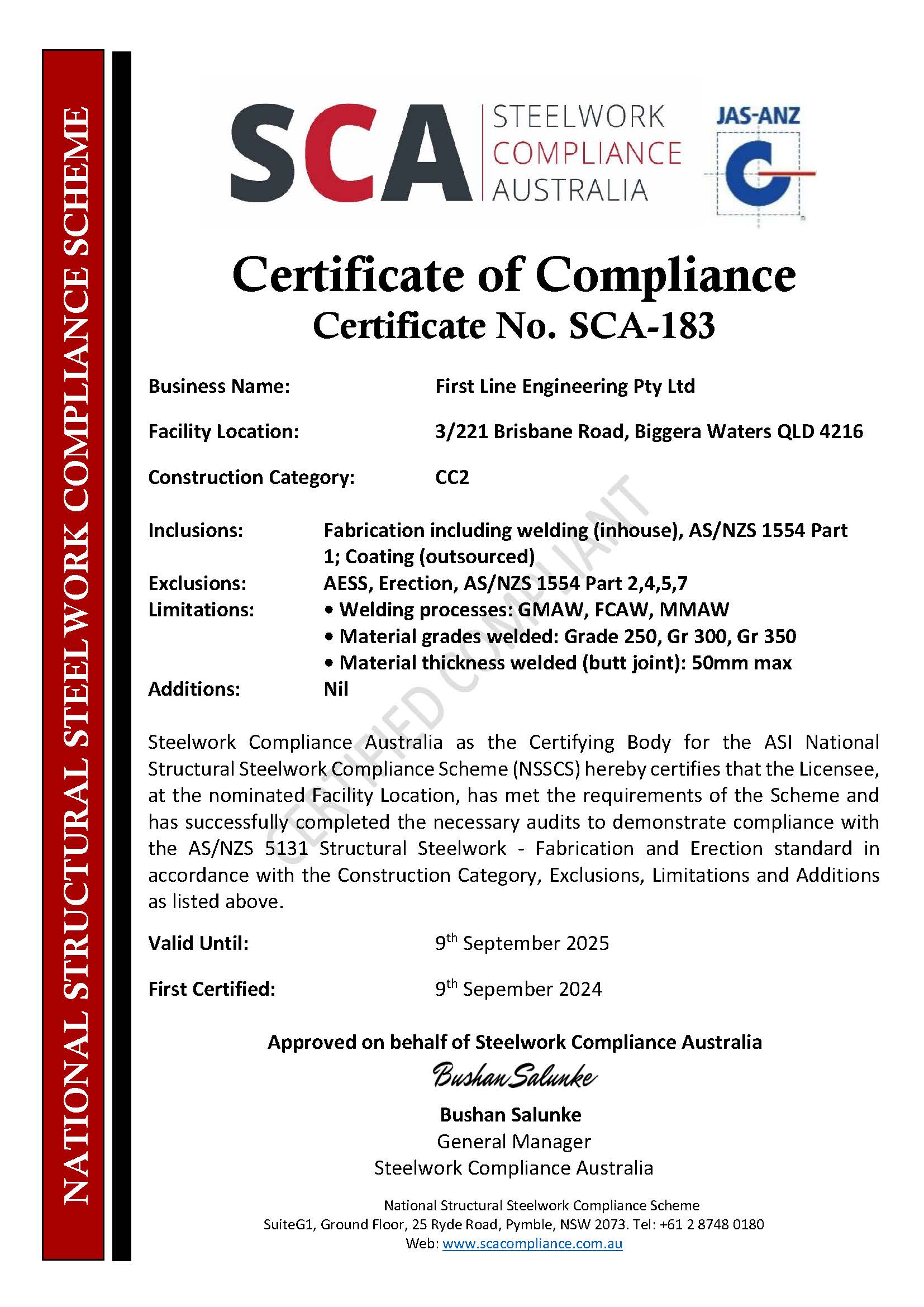

First Line Engineering recently completed a remarkable project in collaboration with Hutchinson Builders. Their expertise was instrumental in delivering the structural package for Thornton, a luxurious apartment development in Kangaroo Point, Brisbane. While Thornton’s architectural brilliance and opulent amenities have garnered attention, it is the exceptional steel craftsmanship by First Line Engineering that forms the backbone of this remarkable project.

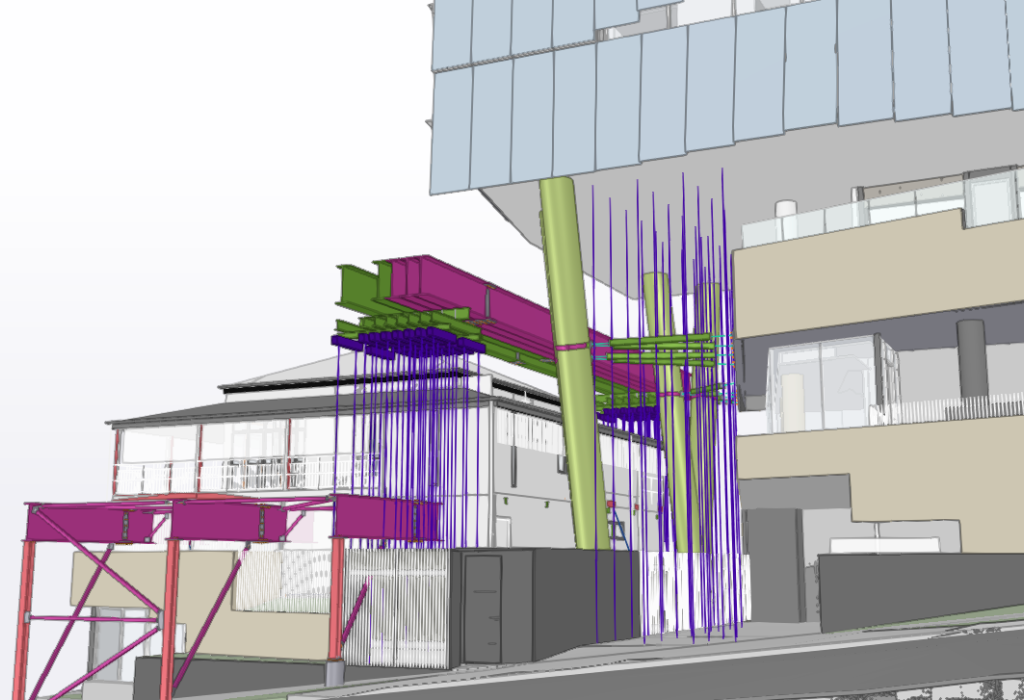

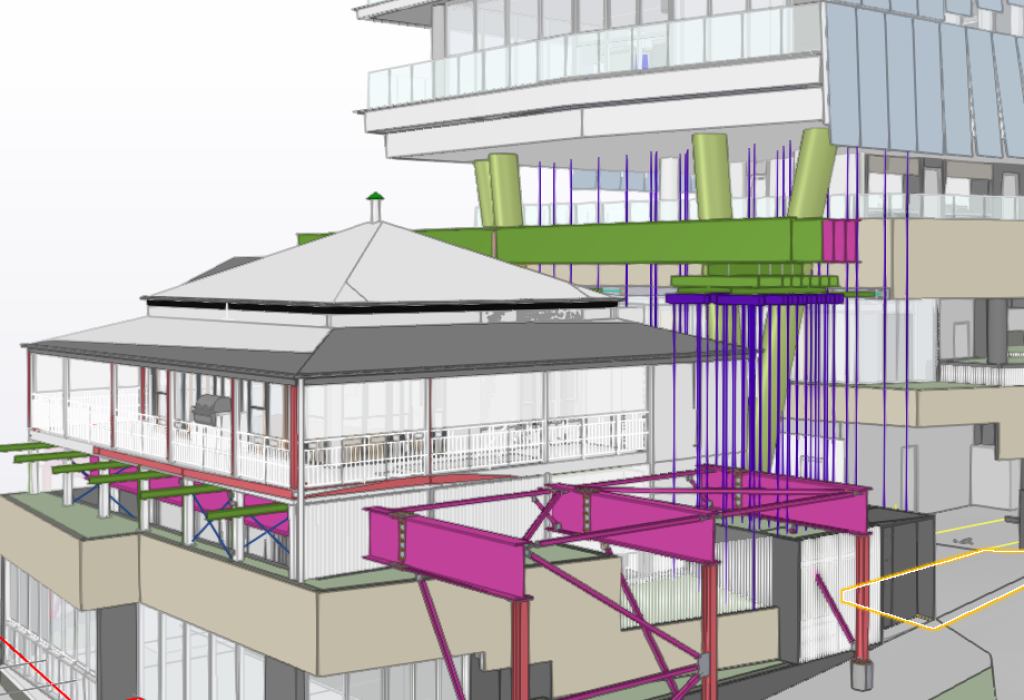

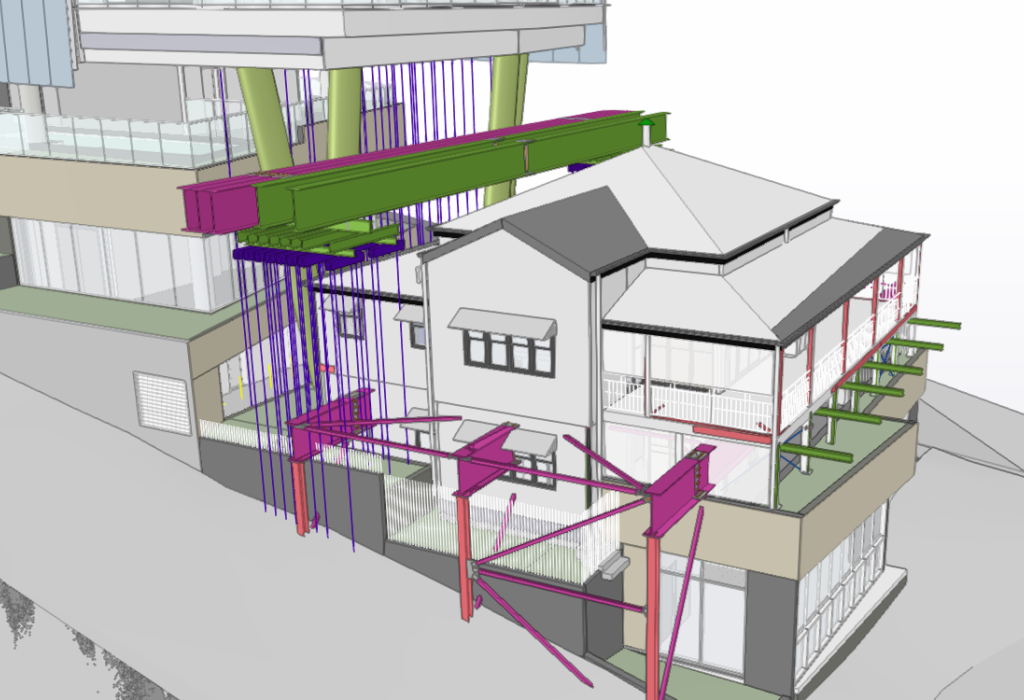

First Line Engineering successfully executed the fabrication and erection of the heritage area, showcasing their strength in handling complex steel structures. The project involved splicing three quantities of 1000WB beams, creating 22-meter long beams weighing 6.6 tonnes each. These beams were transported from the manufacturer in Sydney using an extendable trailer, with each 16-meter stock length weighing an impressive 23 tonnes. First Line Engineering seamlessly joined the 1000WB beams using 204 M24 structural bolts tensioned to 246kN. Overcoming logistical challenges, the fabricated and spliced beams were skillfully transported to the site using a prime mover fitted with a jinker trailer, enabling maneuverability through narrow and steep streets. The installation of columns and tie braces further showcased their prowess, accomplished with the assistance of a 16-tonne city crane and a fully counterweighted 100-tonne crane.

First Line Engineering also fabricated and erected the magnificent feature columns. Measuring 914 x 12.7 CHS, the columns were a prominent structural element. In the workshop, 2.5 tonnes of Reo cages were installed into each column and welded together. The total weight of the completed columns was a sturdy 10 tonnes. Joining of the columns involved a full strength butt weld that was 100% ultrasonic (UT) and magnetic particle inspected (MPI) tested to ensure structural integrity. Custom transport jigs were also manufactured to safely transport the imposing 10 tonne columns to site. Installation was accomplished through a dual lift using a 60 tonne crane and tower crane. The columns were carefully placed on 16 cast-in bolts, landing with little tolerance – a testament to First Line Engineering’s precision and expertise.